1. Pressure setting adjustment of water roller ink roller

Most of our products are printed with UV ink. After using water roller ink roller for a period of time, they will expand to different degrees, which will lead to problems such as water bar ink bar in the printing process. In this regard, we should often check the use of cots, adjust the pressure of water roller ink roller according to the actual use of water roller ink roller.

2. Lubrication of drive bearings of offset press

In the offset production process, the paper is transferred between the printing color groups through the stamping tooth row the paper transfer tooth row. If the lubrication of the transmission bearing is in place, it will lead to the wear of the open tooth bearing, affect the transfer time of the paper between the printing color groups, then lead to inaccurate overprinting of the product, especially in the printing of thin paper products, such phenomenon often occurs, the consequence ratio More serious. Therefore, we should do a good job in the lubrication of the drive bearings of the offset press.

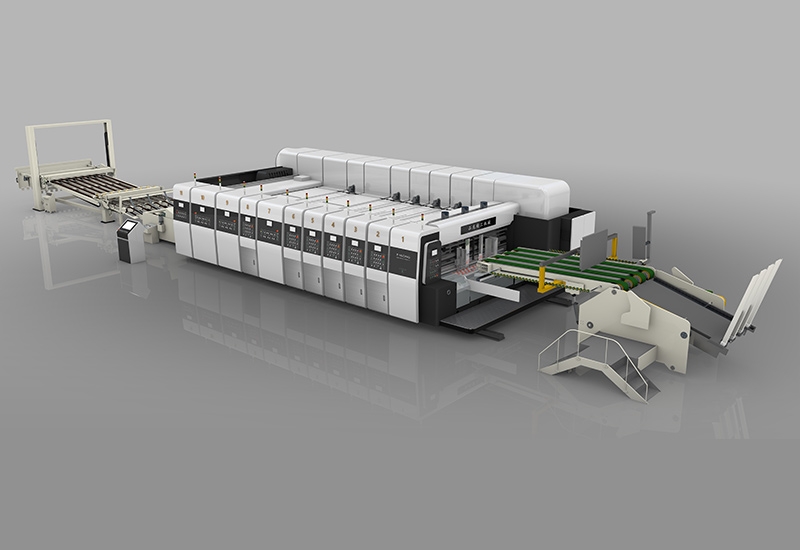

Carton machinery, carton machinery, carton printing machine